Sunylon

| ||||||

|---|---|---|---|---|---|---|

| Recycled Nylon Yarn | 環保回收尼龍紗 | |||||

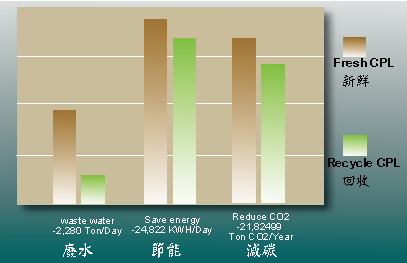

| As technology advances, the standard of living improves significantly and thus, environmental awareness to protect Mother Earth also rises gradually. Today, going " Green " is a trend. The past environmental protection efforts focused on recycling and reducing waste such as PET bottle recycling. Recycling recovery processes that include transportation, cleaning , de-scaling, and shredding process result in consumption of more resources and engery which is not environmentally friendly. Formosa Chemical & Fibre Corporation of Formosa Plastics Group has developed a Nylon Recycling System. This advanced technology extracts water from recycled polymer, and through depolymerization , extracts CPL from manufacturing waste such as waste yarn, waste chips and post-consumer waste. The extracted water and CPL are then recycled for use as raw materials. Formosa's Sunylon Nylon Fiber is 100% made from recycled nylon chips which are produced from recycled CPL. This resulted in an annual savings of 210,600 tonnes of fresh CPL, reduction of waste water and energy, thus reducing carbon dioxide (CO2) emissions by more than 14.9%. Reduction of 21,499 tonnes of CO2/year is equivalent to planting 46,233 trees in 40 years. Sunylon Nylon Fiber is a product that reduces carbon footprint. In June 1999, Formosa became the first manufacturer in Taiwan to receive the Green Mark certification by Taiwan's Environmental Protection Administration (EPA). Following that Formosa not only received international certification from Oeko-Tex100 but also Formosa earn global recycling program certification by Dutchbased Control Union Certifications. | 隨著科技進步, 人類生活水準大幅提升,對地球環境保護的意識也逐步抬頭. 環保已是時代的趨勢, 過去的環保工作只是著重資源回收, 減少垃圾量, 例如保特瓶的回收. 但在回收過程中, 因為運輸, 洗滌, 脫標, 粉碎處理的過程裡卻消耗更多能源, 一點都不環保. 最新趨勢的環保更重視節能減碳, 有關節能減碳的製程及產品都獲得產業界的高度重視, 一向重視環保的台塑企業, 更是帶頭發展. 台塑企業之台化公司發展出耐隆聚合回收系統, 可回收聚合的萃取水及製程中的廢絲,廢塊,廢粒和消費端的回收廢棄物, 再解聚後萃取出其中的CPL原料再利用. 台化的Sunylon®回收環保絲 100%使用回收素材之耐隆粒, 每年減少對新鮮CPL需求量 210,600 公噸, 製程廢水減量及節約熱能可減少二氧化碳排放達 14.9%以上 (減碳 21,499 公噸 CO2 / 年, 等於種樹 46,233 棵 40 年之減碳量 ) 台化的回收環保絲是真正節能減碳的產品, 並在 1999 年 6 月申請成為第一家通過中華民國行政院環保署環保標章認證的廠商, 其後再通過國外 Oeko-Tex100認證.並且榮獲荷蘭 Control Union 全球回收環保認證.

| ||||

| ||||||

|

| |||||

Characteristics of Recycled Yarn

| 產品特性 | |||||

| 1) FCFC uses 100% Recycled CPL to produce nylon chip to make Recycled Yarn. 2) By using Recycled CPL, saving energy & reduce 15% of fresh CPL. 3) Reduce waste water and energy, reduce 14.9% of CO2. (Reduce -21,499 Ton CO2/Year = plant 46,233 tress of 40 years) | (1)台化所生產之環保絲為100%使用回收素材生產之尼龍粒.

| ||||

| ||||||